|

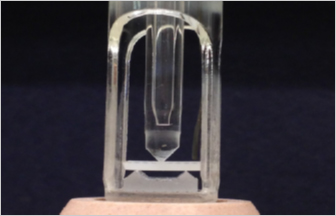

그림5. three point bending geometry used in the heat deflection test.

그림 5와 같이 샘플은 평행한 날카로운 두개의 모서리에 올려놓을 수 있는 사이즈가 요구되며, Probe는 두개의 모서리 사이의 샘플 위에서 세밀한 힘을 가하게 된다.

Probe를 통해 응력이 가해지면 샘플에 받는 Stress가 Strain으로 나타나게 된다.

기본적인 실험 방법은 ASTM D648과 ASTAM E2092 규격에 나오는 열변형온도(HDT), 하중조건에서의 열변형온도(DTUL)를 참고하면 된다.

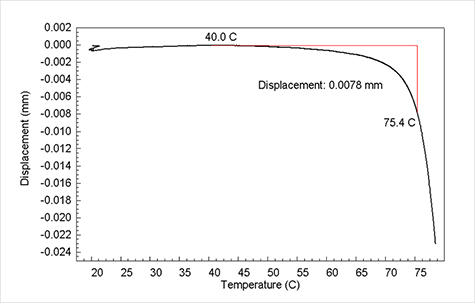

그림6. HDT/DTUL flexure test Heat Deflection at 66 psi (.455 N) of Polystyrene

그림 6는 폴리스티렌의 실험 그래프이다. 66psi 혹은 0.445뉴튼을 적용하기 위해 샘플 면적에 따라 계산된 하중을을 적용한다. 그리고 Strain 이 0.2%가 되는 온도를 측정한다.

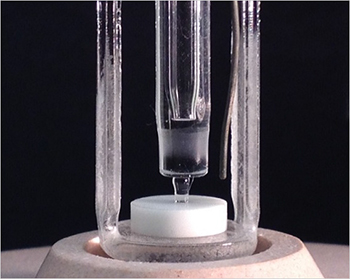

그림7. TMA Geometry for simulated Vicat Softening test

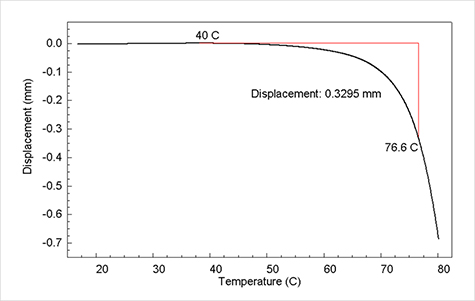

국부적인 Stress의 결과로 샘플이 침투되는 온도를 측정하기 위해 Vicat test를 사용한다. 그림7과같이 TMA에서 실험을 하기 위해 응력을 집중할 수 있도록 Penetration Probe를 사용한다. 0.32mm 침투가 되는 시점의 온도를 측정한다.

그림 8은 다공성의 건축재료인 PVC의 Vicat test 결과이다.

그림8. Softening point by a Vicat-type technique

TMA 4000은 대양한 분야에 적용하는 재료들의 녹는 점과 연화점을 평가할 수 있는 장비이다.

또한 뛰어난 감도로 약한 전이현상부터 녹는 점등 부피변화를 수반하는 모든 현상을 측정할 수있다.

|